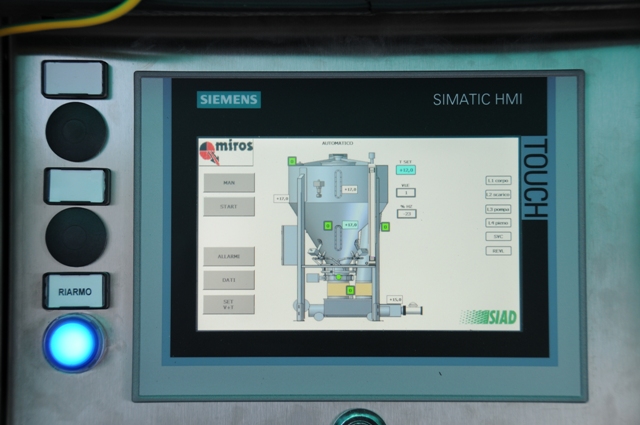

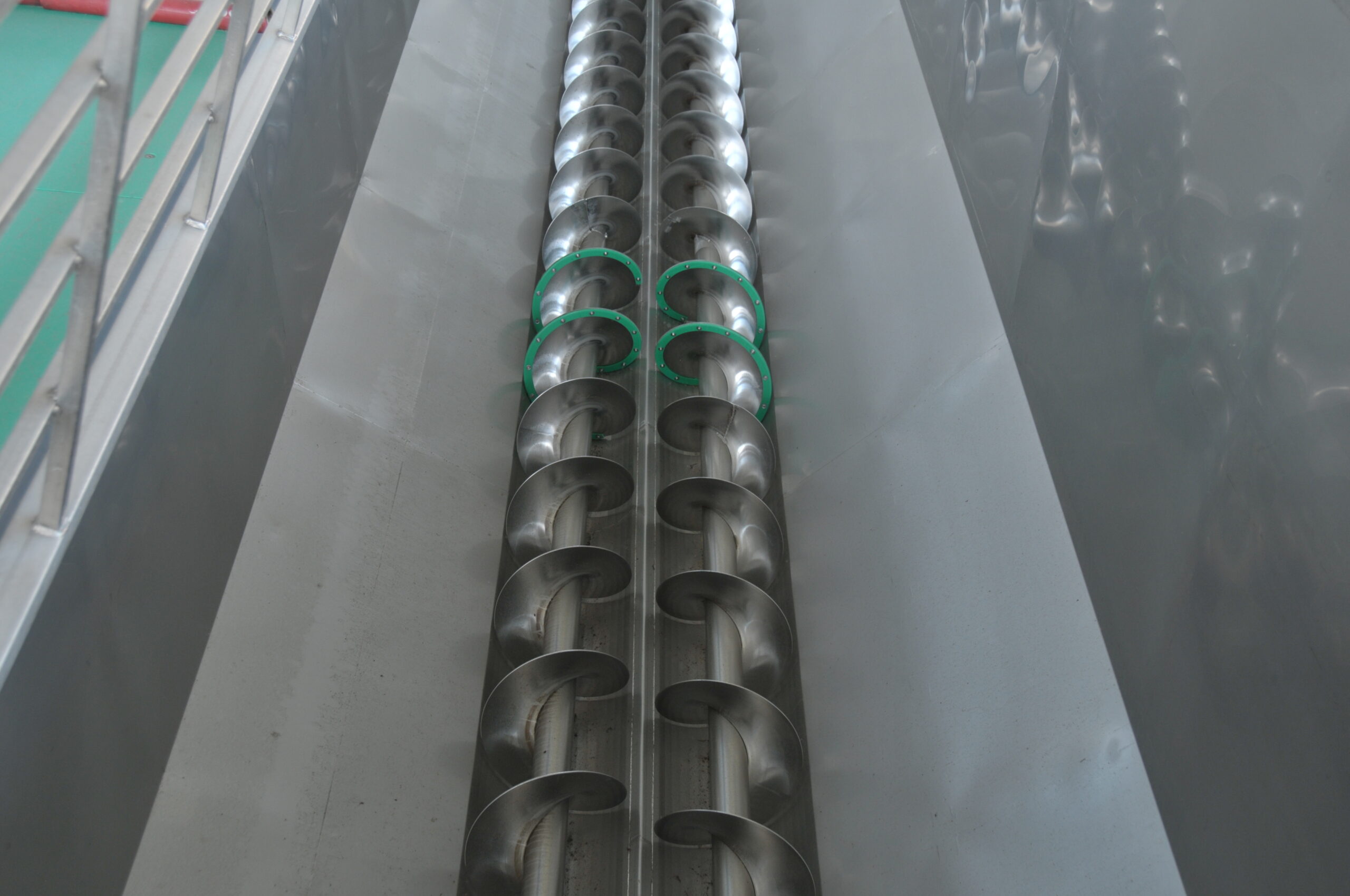

The KRIOS reduces the temperature of any product that you can pump inside with flow rates up to 18,000 / 20,000 kg / h. By setting the parameters of temperature, level we can get up to speed with the machine almost instantly a decrease 15/20 °C. This innovative machine can be used interchangeably on all food products and not, that can be pumped inside, the building materials are totally in stainless steel AISI 304 (AISI 316 on request for additional charge) or in materials suitable for contact with foods, and it has been properly certified to meet the European directives on safety at work. It is a unique machine in its category, the working principle is the only one able to allow a correct homogenization of the product to be cooled with the gas injected inside the cooling chamber and which allows to maximize the cooling power developed in the case of food products such as grapes or fruit without causing cold burns. The shape of the machine has been conceived in order to plan the inner part without problems and with reduced times, the preferred automatic washing system controlled by the electronic processor and the practical portholes allow the washing whenever you wish in about 5/10 minutes. The presence of numerous accessories and controls allows the machine to be inserted within the processing chain and check its procedures with practicality and safety of personnel.

Data sheet

PDF KRIOS_Operating technique KRIOS_Technical data

Italiano

Italiano